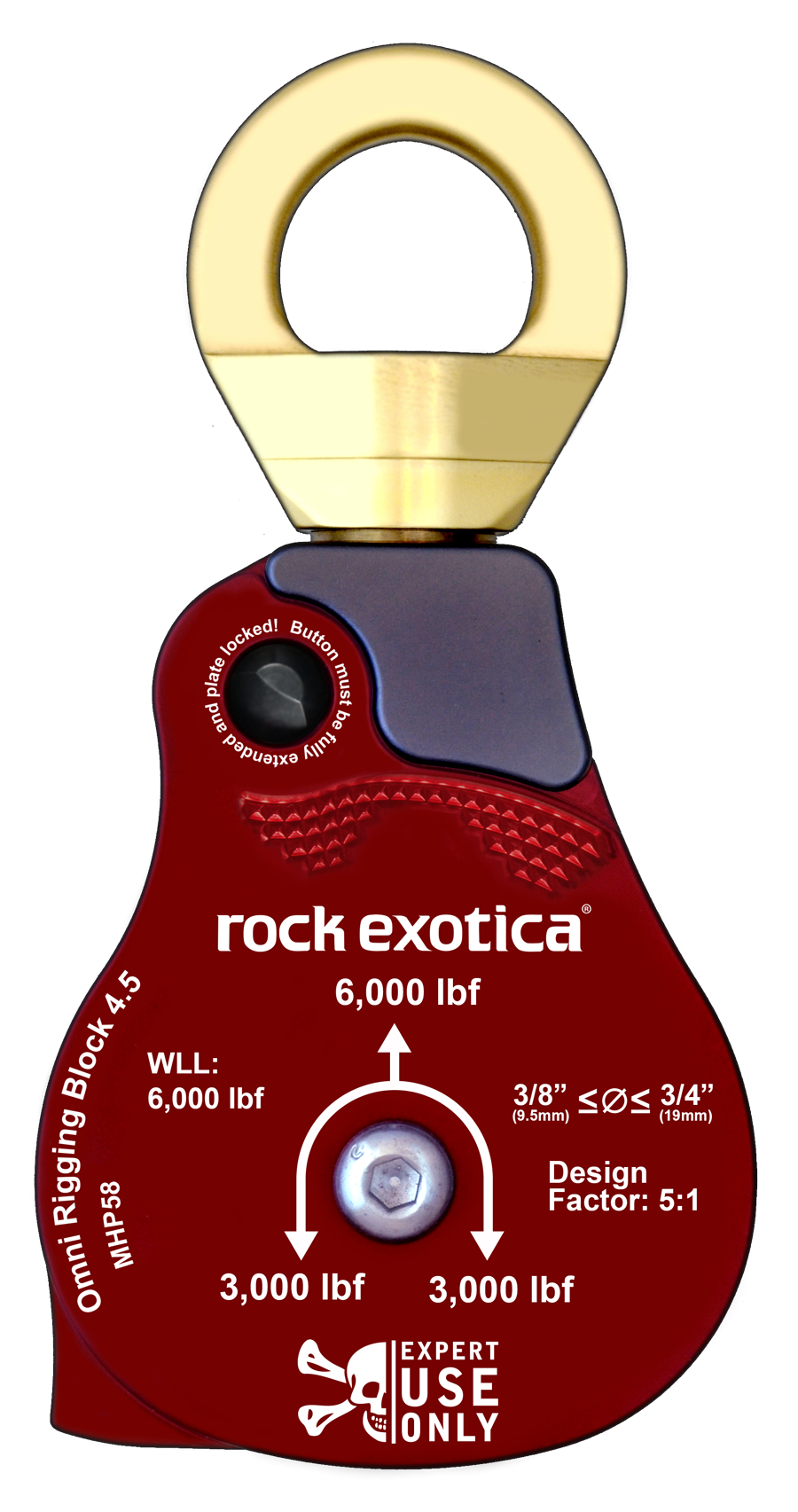

Product Overview

OMNI-BLOCK

FEATURES & BENEFITS

The Omni-Block combines a swivel and pulley into one tool, and incorporates a unique sideplate that opens while the pulley is still attached to the anchor. Traditionally, a pulley is connected to a swivel by a carabiner. However, the Omni eliminates the need for the carabiner, reducing length and pieces of equipment in the rigging system. The short length of the Omni is important when used in high-angle, confined space or other space-sensitive rigging environments. The reduced weight of the Omni will make hauling your gear easier. Additionally the Omni sideplate can be opened without detaching from the carabiner. Traditional pulleys require removing from the carabiner to change the rope. With the Omni, the user is able to do this while the pulley is still secured.

- Install and remove rope while still connected to the anchor

- Sideplate locks with two-stage, double-catch safety mechanism

- Integrated swivel allows pulley to orient while reducing gain

- Connect, install and remove rope with one hand

- CNC machined for optimal weight & strength

HOW IT'S MADE

The Omni Swivel Pulley is made the same unique way that many of Rock Exotica products are made—from solid material. The design and function of the pulley require a strong core from which the sheaves, side plates, and swivel top must connect. For this we rely on the capability of our state of the art machining centers to take a solid block of aluminum and cut away material to create this integral part.

With precision available only on such a machine, the block of aluminum is transformed into an axle, head piece, becket, and release button housing all in one. The result is a pulley that is lighter, stronger, and more compact than those made by traditional methods and stamped parts.

WE FOUND OTHER PRODUCTS YOU MIGHT LIKE!

- Opens in a new window.